In recent years, almost all vehicles launched on the market use injection fuel supply systems, and the main reason is to respond to increasingly stringent environmental regulations. The injection fuel supply system has evolved from the early mechanical single-point injection to the current electronic multi-point injection. So, what is single-point injection and multi-point injection? Assuming a four-cylinder engine, with a single fuel injector placed before the intake manifold branch, the fuel is injected from one place and then distributed to the four cylinders with the intake air. This is single-point injection; and the fuel injector is placed in the intake duct of each cylinder of the four cylinders, because each cylinder has a fuel injector, and the four-cylinder engine has four fuel injectors, this is called multi-point injection. This unit will discuss the principle of the currently widely used multi-point injection.

From the perspective of the fuel path, first the fuel pump sends the fuel from the fuel tank to the fuel pipe, and the fuel pipe then sends the fuel to the fuel rail, and the fuel rail is controlled by a pressure regulating valve to control the fuel pressure and ensure that the fuel pressure sent to each cylinder is the same. On the other hand, the pressure regulating valve will also release the excess fuel to the return pipe and flow back to the fuel tank. One end of the fuel injector is connected to the fuel rail, and the nozzle is on the intake duct of each cylinder. The engine ECU will issue a fuel injection command to the fuel injector according to the engine operation status. The amount of fuel injection is determined by the fuel pressure and the injection time of the fuel injector. The fuel pressure is controlled by the pressure regulating valve at the fuel rail, and the pressure of the fuel pressure regulating valve is adjusted by the manifold vacuum (engine load). Therefore, the ECU can control the injection time. When the engine needs more fuel, the injection time will be longer, otherwise the injection time will be shorter

The fuel injector itself is a normally closed valve (a normally closed valve means that when there is no input control signal, the valve is always in a closed state; while a normally open valve means that when there is no input control signal, the valve is always in an open state), and a valve needle moves up and down to control the opening and closing of the valve. When the ECU issues a fuel injection command, its voltage signal causes current to flow through the coil in the fuel injector, generating a magnetic field to attract the valve needle, allowing the valve to open so that the fuel can be sprayed out from the injection hole.

The biggest advantage of fuel injection is that the fuel supply is very precisely controlled, so that the engine can have the correct air-fuel ratio in any state, not only keeping the engine running smoothly, but also its exhaust gas can meet the standards of environmental regulations.

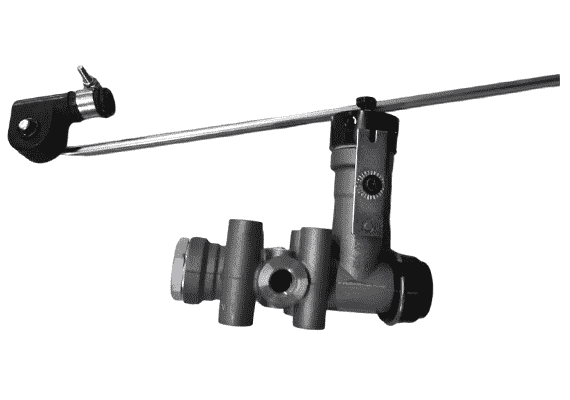

Geniune Wabco 4613170060/DP002105/84521306032 Foot Brake Valves For Sell

Original Wabco Altitude Valve 4640050020 For Trucks

Wabco Air Line Filter 4325000200/4325000210 For Trucks Spare Parts

Knorr 0486203014/20374445/0486203033X50/0486203014204 EBS One Channel Module For Trucks

Genuine Wabco 4729000010/AB4729000010/0527488 ECAS Solenoid Valves For Sell

Wabco 9710020400/S9710050020/2090230 Relay Emergency Valves For Trucks

Original Knorr K040954K50/SN7274RC Brake Caliper For Trucks

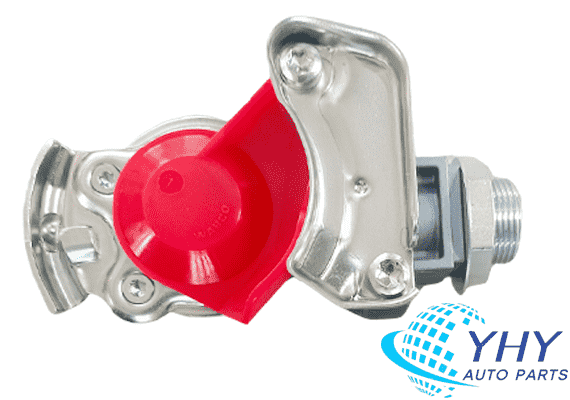

Wabco Premium Original Quality 9522010010/1518206/5058203290 Coupling Head with Integrated Filter For Sell

Tel