There are two main reasons for oil leakage: oil seal damage and connecting rod surface damage.

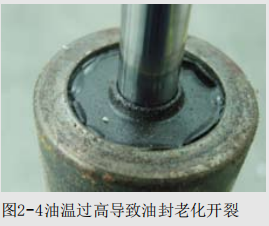

1.The oil temperature is too high, causing the oil seal to age and crack, as shown in the figure; resulting in oil leakage and damping failure, it must be replaced

2.The lateral force is too large, causing serious eccentric wear of the connecting rod, as shown in Figure 2-5. This causes oil leakage and damping failure, and must be replaced.

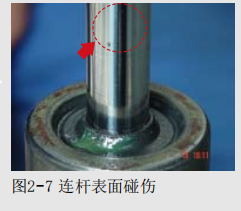

● There are two types of connecting rod surface damage:

1) Excessive lateral force causes abnormal wear of the connecting rod surface in the working section, as shown in Figure 2-6, resulting in oil seal damage, leakage of working oil, and the shock absorber must be replaced.

2) The connecting rod surface is damaged. As shown in Figure 2-7.

The oil seal is damaged, the working oil leaks, and the shock absorber must be replaced.

Recommended method for determining oil leakage on site: Pull the shock absorber to its longest position and observe the part covered by the dust cover. If the reservoir of this part is dry and has no oil stains, it can be determined that the shock absorber is not leaking oil. For shock absorbers that are determined not to be leaking oil, they can be reinstalled and used on the vehicle without replacing the shock absorber.

If there are signs of oil dripping from the part covered by the dust cover, it can be judged as oil leakage. The shock absorber with oil leakage needs to be replaced.

Genuine Wabco 4123520290/7421353457/21353457 Single-Cylinder Compressor For Trucks

Wabco 4630840000/867872/4425013800/1738469 Lift Axle Control Valves For Trailers

Genuine Wabco 4801041060/81521066058/81521066039 EBS Axle Modulator For Trucks

Wabco 9617230380/3454402520/451405890A Hand Brake Valves For Trucks

Genuine Knorr K105481N00/AC577AF Relay Valve For Sell

Wabco 9254610320/002399/4454105600/2090332 Spring Brake Cylinder For Sell

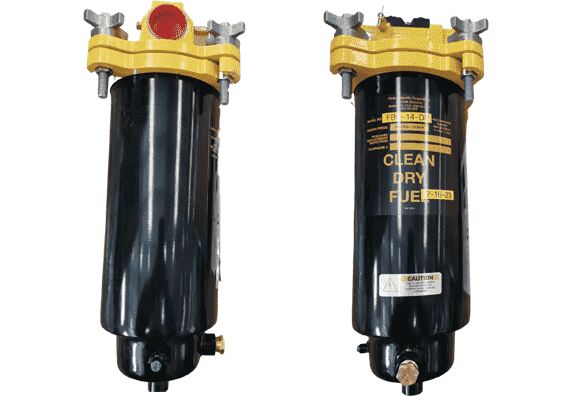

Parker-Racor Fuel Filtration Assemblies FBO-14-DP For Sell

Wabco EBS Trailer Control Valve 4802040300/A0014311213/MX917088 For Trucks

Tel